Find the

Right Product

Utilize our PRT+ tool to identify the ideal onsemi product for your specific application with maximum efficiency.

Find ProductsFind the

Ideal Solution

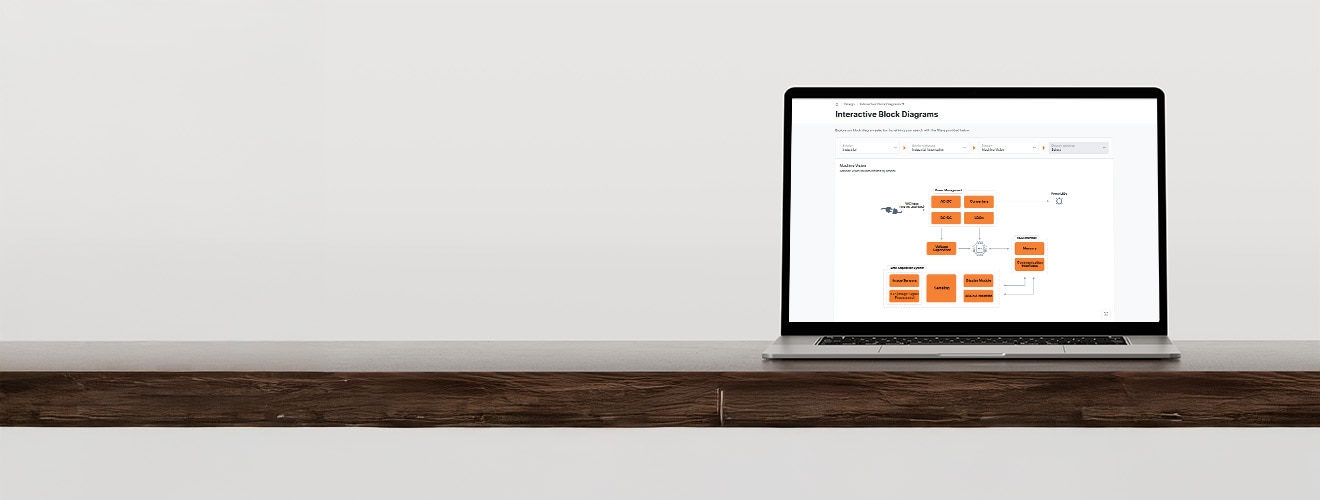

Our user-friendly 极速 赛车_168开奖官网_开奖视频 | 极速赛车168赛车官方最新结果公布 - 现场直播开奖记录每一分钟数据 system solution guides, invaluable resources that explain onsemi's product range for different applications.

Explore NowFind the

Right Document

Search through datasheets, application notes, and white papers to locate the relevant information.

Find DocumentsTalk to Our

Sales Team

Have questions about our 极速赛车_168开奖官网_开奖视频 products and 极速赛车168赛车官方最新结果公布、现场直播开奖记录每一分钟数据 services, or need help with a design? Our sales support team is here to help!

Contact SalesAnnual Sustainability Report 2023

Our 2023 sustainability report details our efforts concerning environmental, social and governance initiatives.

Read ReportTransform Your Future at onsemi

Join a team where cutting-edge intelligent technologies enable world-leading innovators and shape the future.

Learn More